Tube & Pipe Manufacturing Processes

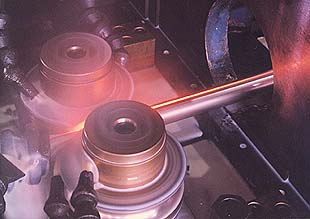

5.HIGH FREQUENCY WELDER – Formed tubes are continuously welded at the seam by the latest technology – AEG Elotherm High Frequency Welder.

6.TUBE SIZING – Welded tubes goes through a series of precision engineered sizing rolls to obtain a precise tube dimension all round.

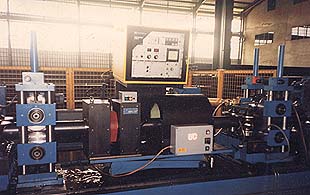

7.EDDY CURRENT TESTER – Tubes are tested for defects in welding by Eddy Current LAB 2 with the highest precision. Compulsory testing is performed on all water pipes.

8. COMPUTER CONTROLLED FLYING SAW – Tubes are precision cut to specific length. Burr free cuts are assured by the high quality cold saw.

| Back

| | Next |

| Tube & Pipe Manufacturing Process | | Tube

& Pipe Products |

|

Tube & Pipe | | C-Channel

| | Galvanized Iron Wire Mesh | | Megastrong

Roofing Sheet |

| Europa Steel Tile Sheet | | HDPE

Water & Chemical Tank |